Screen Gaskets

Screen Gaskets

Our screen gaskets are not used the same way as conventional filters, although they can be considered a filter. Conventional filters are built differently and have many layers to prevent particles to pass through, these can reach efficiencies of almost 100%. A particle comes in many different shapes. For example, a hair has a diameter of Ø 0,1 mm but the length can be centimetres long. If the hair arrives perpendicular to the screen it might pass a 100 mesh screen. With a conventional filter, the second or third layer will prevent the hair to pass. Retention’s of standard screens are calculated according to international standards using perfectly round glass spheres. Our screens are only one layer and therefore they cannot be considered the same as a filter. Each screen gasket has a high-performance gasket made out of one of the validated compounds that we use for our standard Sanitary Gaskets range.

Screens molded our standard

Screens molded our standard In many upstream and downstream processes, it is sometimes required to do an inline or in situ filtration step. It is usually meant to capture isolated particles created by moving parts in the system. Deterioration of valve membranes, pumps or gaskets can generate these kinds of particles.

In a start-up phase, it can be used to protect pumps from large items that accidentally fall in the system and are flushed through causing major damage. Filling needles can be equipped with a fine filter down to 10µm to capture anything that should not be there before the vial is sealed.

Available Sizes

- 1/2″ through 4″ (TC 25 -TC 119)

- DIN32676 A, B, C same TC diameters

- CMD-1004 EPDM black

- CMD-1010 FKM black

- CMD-1012 Platinum Silicone Translucent

- CMD-1028 PTFE white

- CMD-1019 Steam-Flon®

Sock Screen gaskets

Sock screens offer a greater soil collection capacity than standard flat screens. They are available in 150 mm (5.91″) and 50 mm (1,97″) lengths. If the capacity of a standard flat in situ filters is not sufficient then the Sock Screen is a good alternative.

The sock screen is supplied with a removable elastomeric seal. Not bonded.

PTFE seals are now available for this product, due to a new moulding technology.

Steam-Flon®is either removable or moulded.

The sock screen is supplied with a removable elastomeric seal. Not bonded.

PTFE seals are now available for this product, due to a new moulding technology.

Steam-Flon®is either removable or moulded.

Available Sizes

- 3/4″ through 4″ (TC 25 -TC 119)

- DIN32676 A, B, C same TC diameters

- CMD-1004 EPDM black

- CMD-1010 FKM black

- CMD-1012 Platinum Silicone Translucent

- CMD-1028 PTFE white

- CMD-1019 Steam-Flon®

Removable Screen gaskets

The in situ filters are collecting particles and therefore they need to be replaced or cleaned regularly. We offer a system with removable gaskets allowing a better cleaning process. The screen can be removed from the gaskets and cleaned in an ultrasonic bath.

After cleaning they can be assembled and sterilized and placed back in the system.

Available Sizes

- 1/2″ through 4″ (TC 25 -TC 119)

- DIN32676 A, B, C same TC diameters

- CMD-1004 EPDM black

- CMD-1010 FKM black

- CMD-1012 Platinum Silicone Translucent

- CMD-1028 PTFE white

- CMD-1019 Steam-Flon®

Double mesh Sintered Screen gaskets

When entering the area of finer mesh sizes we recommend the use of sintered mesh screens. The screen is built up with a supporting screen and a fine mesh screen on top. These are “welded” together and cannot be separated. This Double mesh product provides better pressure resistance and is suitable for backwashing cycles.

The double mesh sintered screens cannot be moulded in elastomers.

The double mesh sintered screens cannot be moulded in elastomers.

Available Compounds

- CMD-1004 EPDM black

- CMD-1010 FKM black

- CMD-1012 Platinum Silicone Translucent

- CMD-1028 PTF

- CMD-1019 Steam-Flon®

What you should know

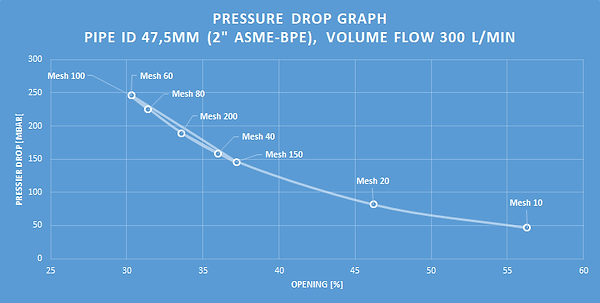

Screens can also be used at the point of use in WFI systems, it is fascinating to know that the pressure drop over a 2” screen with 150 mesh is only 150 bar at 300L/min. Frequent cleaning of the screen is required because the captured particles will create a higher pressure drop eventually.

Standard Screen material is 316SS

DIN32676 series A, B, and C.

- DIN32676 Series A

- ISO1127 (DIN32676 Series B)

- ASME BPE (DIN32676 Series C)

- ISO2852

- SMS3017

- DIN11851

- DIN11864

- DIN11853

- SMS1149-L

- BS4825