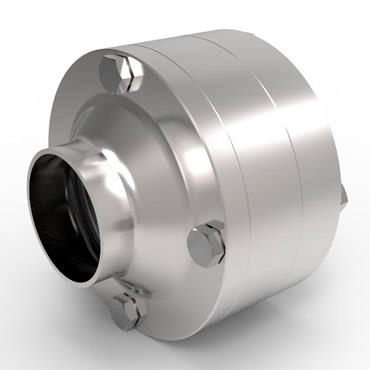

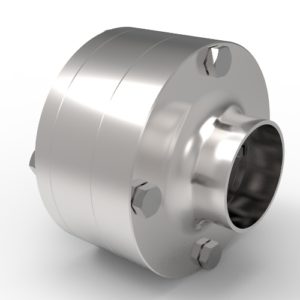

EDF VALVE

CHECK VALVE EDF

- No more springs that can break or jam.

- No intermediate components to prevent flow.

- No stagnation points.

- No maintenance required.

BENEFITS

- Maximum hygiene: Only the shutter comes into contact with the product. No stagnation points, no springs or other intermediate components that could contaminate it

- Closing and sealing guarantee: Secured by the patented magnetic principle

- Free positioning: Unlike other types of springless valves (such as ball valves), Ygros EDF retains its functionality on both horizontal and vertical installations.

- Energy saving: Operating principle and innovative design allow a fluid and free passage, thus minimizing turbulence and pressure drops.

- Laminar flow: Minimizes turbulence

- It does not require maintenance

- Long valve life: Thanks to the high chemical resistance of the construction materials used

TECHNICAL DATA

Materials in contact with the product | Body and flanges: Stainless steel 1.4404 (AISI 316L) |

Materials not in contact with the product | Magnet: Neodymium |

Gaskets | EPDM, NBR, HNBR, VMQ (Silicone), FKM (Viton) FEP, PTFE |

Surface finishes | Internal: Ra µm ≤ 0.8 (standard) up to Ra µm ≤ 0.4 electropolished and passivated (optional) |

Flanges available | WELDING: DIN 11850 / DIN 11851 / ASME BPE / ISO 1127 / SMS |

Temperature Range | -40 ° C / + 150 ° C (Standard). Up to + 220 ° C (optional) |

Operating pressure | PN16 (standard). Other pressures on request |

Treated products | Liquids, gases, steam |

Certificates (on request) | MATERIALS: EN10204-3.1 / O-Ring (FDA) / Surface roughness |

|

YGROS EDF: STANDARD OPENING PRESSURES

|

||

|

Installation |

Direction of flow |

Opening pressure |

|

HORIZONTAL |

30/50 mbar |

|

|

VERTICAL |

Descending Flow |

27/45 mbar |

|

VERTICAL |

Ascending Flow |

33/55 mbar |

|

Once the valve is open, a pressure of about 10 mbar will be enough to keep it running. |

||

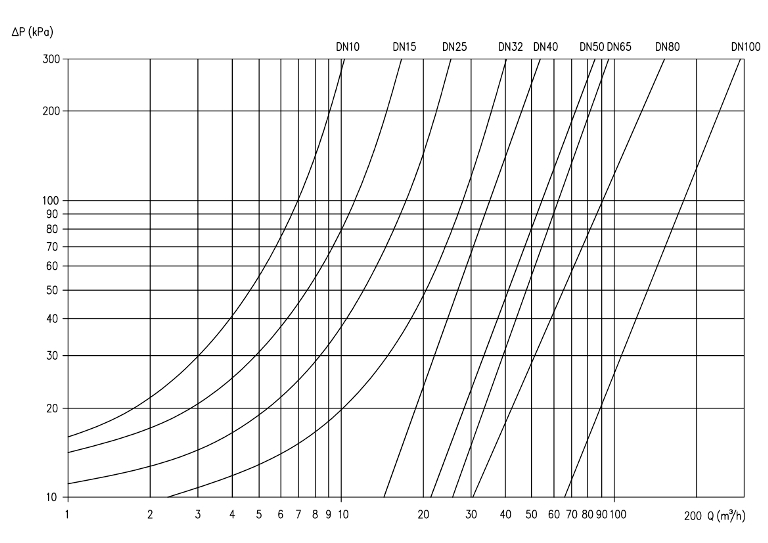

PRESSURE LOSS GRAPH