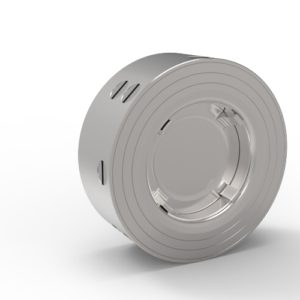

WAFER VALVE

WAFER CHECK VALVE

- No more springs that can break or jam.

- No intermediate parts that could impede the flow.

- No flickering.

- No stagnation points.

- No maintenance required.

BENEFITS

- Absence of vibrations and flickering: this innovative principle is particularly advantageous in systems where the fluid is compressible (such as gases) or is treated at low pressures; in fact the Ygros WAFER valve remains open with a minimum pressure difference.

- Chemical resistance: thanks to the construction in 1.4404 (AISI 316 L) and 1.4462 (Duplex), which also guarantees a longer life of the valve

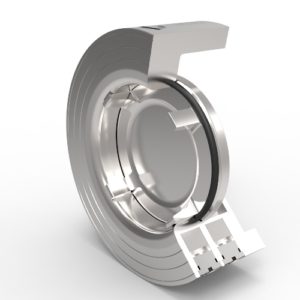

- Closure and sealing guarantee: ensured by the patented magnetic principle.

- Free positioning: Ygros WAFER maintains its functionality both on horizontal and vertical installations.

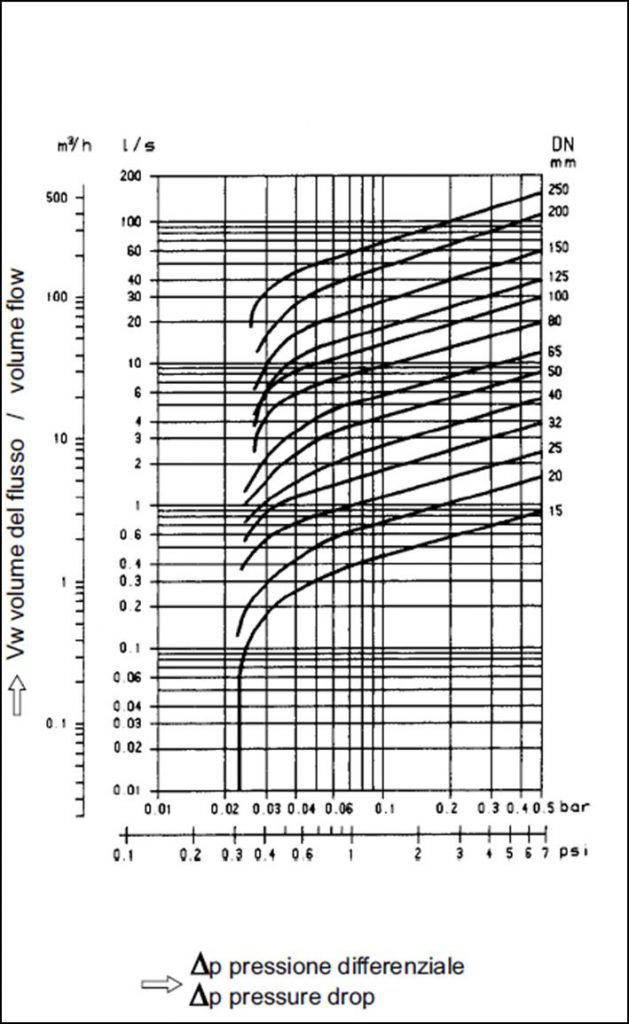

- Energy saving (laminar flow): operating principle and innovative design allow a fluid and free passage, thus minimizing turbulence and pressure drops

- It does not require maintenance

TECHNICAL DATA

|

Materials in contact with the product |

Body: Steel 1.4404 (AISI 316L) |

|

Materials not in contact with the product |

Magnet: Neodymium |

|

Gaskets |

EPDM, NBR, HNBR, VMQ (Silicone), FKM (Viton) |

|

Surface finishes |

Internal: Ra µm ≤ 1.6 (standard) |

|

Temperature Range |

-40 ° C / + 150 ° C (Standard). Up to + 220 ° C (optional) |

|

Operating pressure |

PN16 (standard). Other pressures on request |

|

Treated products |

Liquids, gases, steam |

|

Certificates (on request) |

MATERIALS: EN10204-3.1 / O-Ring (FDA) / Surface roughness |

|

YGROS WAFER: STANDARD OPENING PRESSURES

|

||

|

Installation |

Direction of flow |

Opening pressure |

|

HORIZONTAL |

10/30 mbar |

|

|

VERTICAL |

Descending Flow |

7/27 mbar |

|

VERTICAL |

Ascending Flow |

13/33 mbar |

|

Once the valve is open, a pressure of about 10 mbar will be enough to keep it running. |

||

PRESSURE LOSS GRAPH